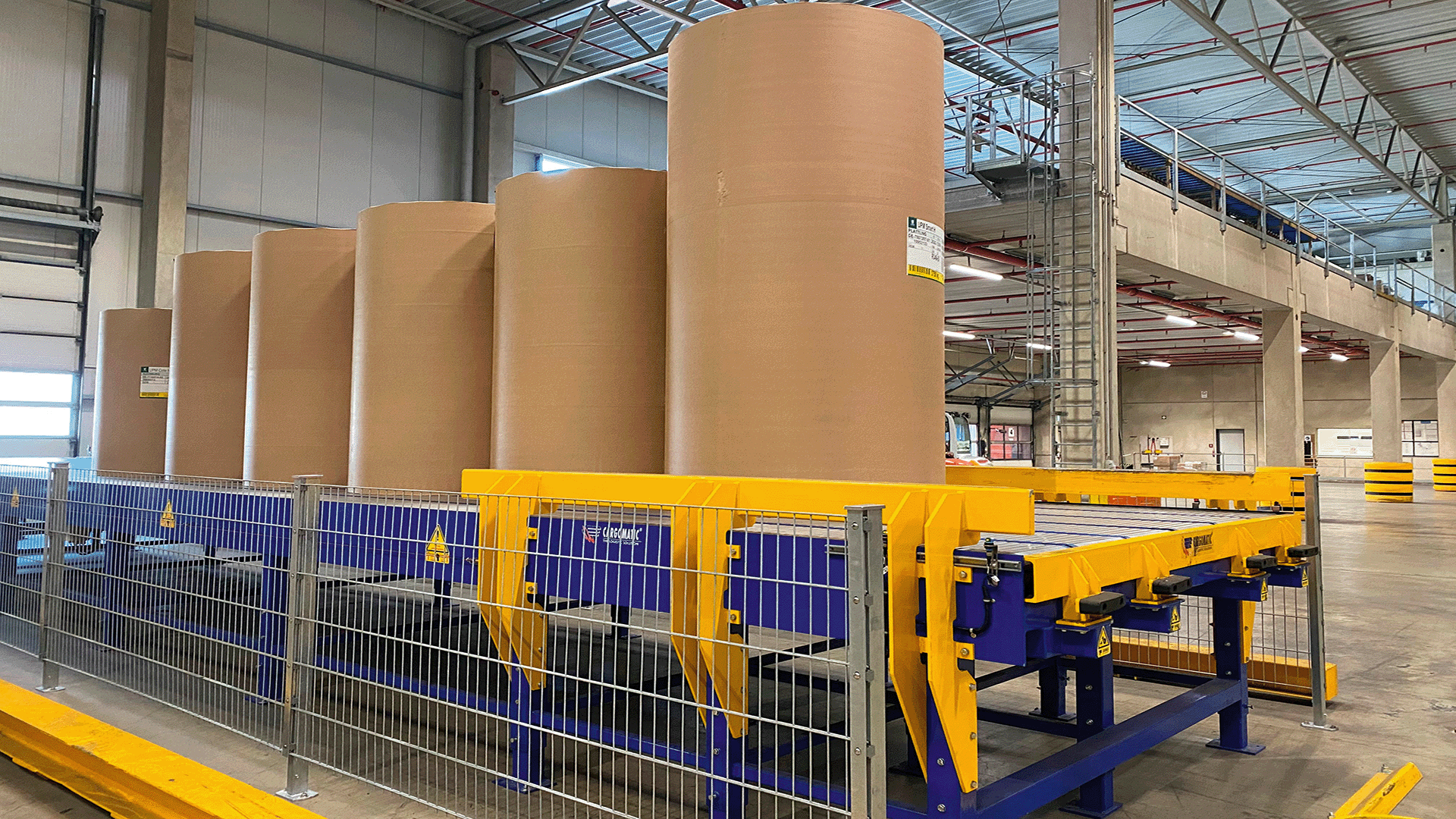

Efficient and safe loading and unloading with CargoMatic

The solution for various industries!

Optimization of loading and unloading processes

In modern logistics, optimizing loading and unloading processes is essential for improving efficiency and safety. The CargoMatic, an advanced transport system, offers the ideal solution. This system is specially designed for automatic loading and unloading of packaged and palletized goods in various industries, without requiring modifications to the trailer.

Automatic goods transportation

CargoMatic is a mobile loading and unloading system that functions as a conveyor belt along the full length of the trailer. The system uses a slat floor that automatically moves goods forward or backward, making the use of a forklift or pallet truck inside the trailer unnecessary. This significantly speeds up the loading and unloading process while increasing efficiency and safety.