Automatic Truck Loading and Unloading Systems:

the Future of Logistics

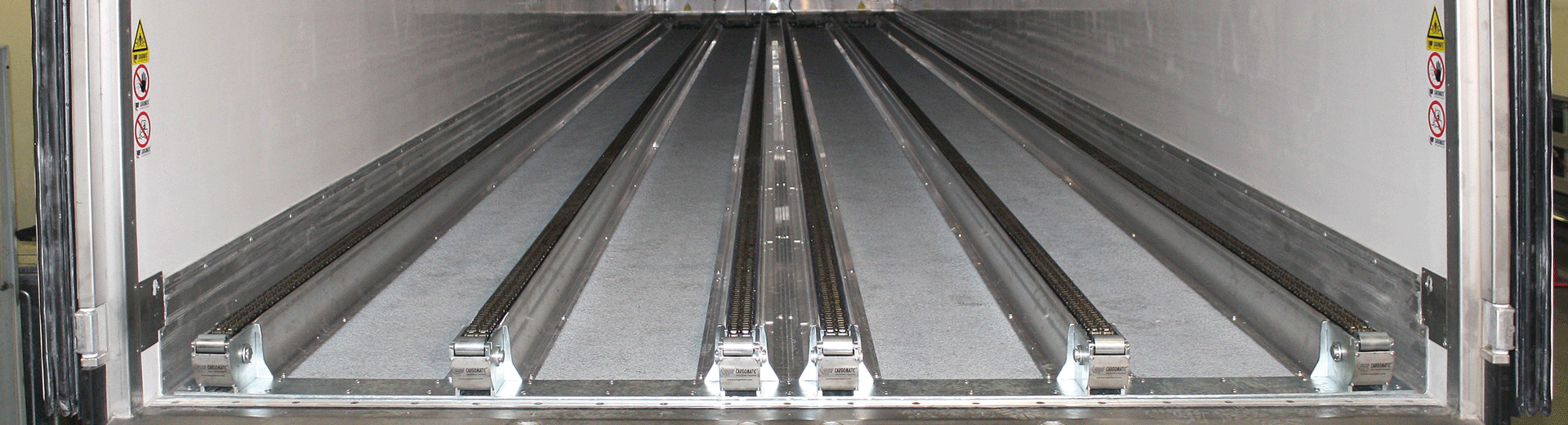

In the world of logistics and transport, efficiency and time savings are crucial. Automatic Truck Loading and Unloading Systems (ATLS) offer an innovative solution that significantly speeds up the loading and unloading of goods. With such a system, a truck can be fully loaded or unloaded in less than 2.5 minutes, which represents a major time saving compared to traditional methods that typically take about 30 minutes.

How Does an Automatic Loading and Unloading System Work?

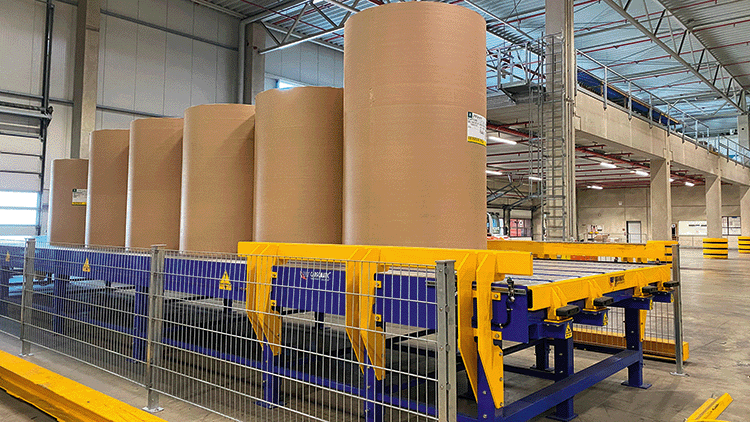

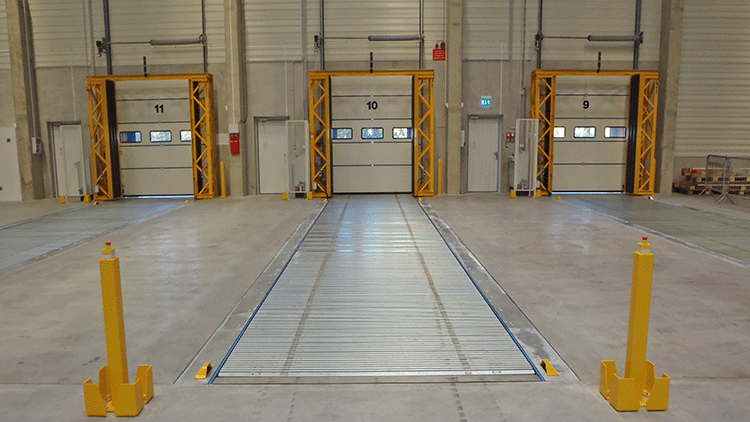

In an automatic truck loading and unloading system, goods—such as 33 Euro pallets—are pre-positioned on a stationary slat or chain conveyor. When the truck arrives and docks at this conveyor system, the load can be automatically transferred into the truck at the push of a button.

Upon arrival at the unloading location, the truck is connected to the stationary system, and the entire load is unloaded in less than 2.5 minutes. The pallets transported onto the stationary conveyor system can then be removed after the truck departs, while the truck picks up the next prepared load.